Vertical multistage centrifugal pumps troubleshooting

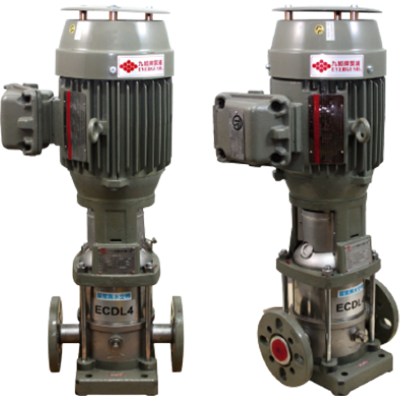

ECDL series

ETS series

※ Before you dismantle the pump or open terminal box, please make sure the power has turned off.

| Unusual phenomenon | Malfunction Routine/Cause | Solutions |

| The pump can’t start. |

|

|

| After it starts, overload protector stops the motor. |

|

|

| The starter closes the motor sometimes. |

|

|

| The pump won’t start after the starter is connected. |

|

|

| Capacity is not stable |

|

|

| The pump is running, but no water coming out. |

|

|

| After the power is turned off, the fan turned reverse. |

|

|

| The mech. seal is leaking. | 1. The mech. seal is damaged. |

|

| Noise |

|

|

English

English  繁體中文

繁體中文