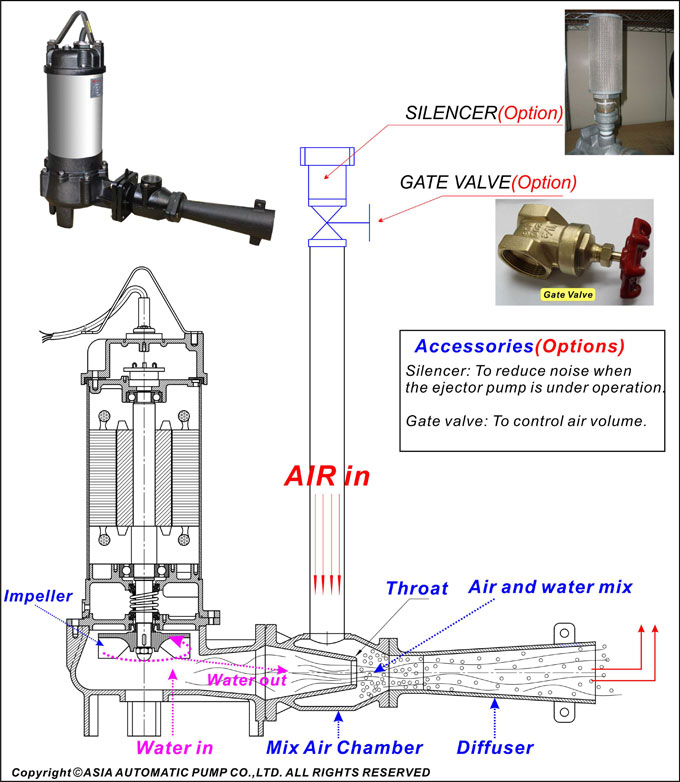

Features:

- High oxygen transfer rate, BOD easy to remove from wastewater treatment.

- Mixing and stirring applications for uniform MLSS due to fine bubbles convention.

- Dry motor with overload protector; Cable with an epoxy resin sealed water-proof cable hood; Use deep groove C3 bearing to extend life time.

- Superior abrasion resistant dual mechanical seals made of SIC material to ensure best seal effect and reduce abrasion from sewage.

Applications:

Oxygen aeration of wastewater for wastewater treatment.Oxygenated for aquaculture such as fishing farming,shrimp farming or hydroponics applications.

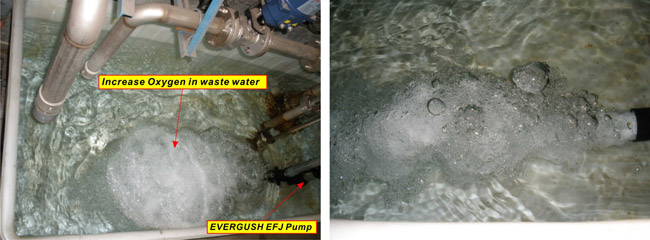

Actually Application Diagram:

Operating Conditions:

- Ambient Temperature: Max.40℃

- Liquid Temperature: 0~40℃

- Forbid 24hr continously running and Forbid running submersible pump under Lowest Running Water Level.

Specifications:

- Power: 1/2HP~7.5HP

- Protection: IP68

- Insulation: F

- Pole: 2P

- Voltage:

Single phase110 or 220V*60HZ(0.5HP~2HP) 3 Phase 220~480V*60Hz

Single phase 220~240V*50HZ(0.5hp~2hp) 3 phase 380~415V*50Hz - Air pipe Dia.: 40mm for 0.5~3HP ; 50mm for 5~7.5HP

- Rated Air: 5~100 M³/Hr

- Rated OTR:0.12~3.3 Kg-O2/Hr

- Water Depth:1.5~4M

.jpg)